Maintenance

Sectorized rotors

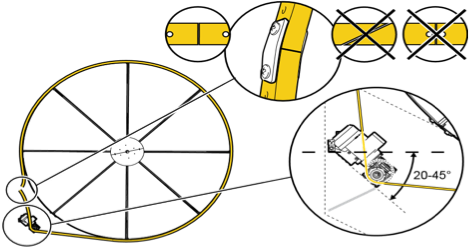

Check all periphery plate fasteners. Retighten fasteners. Tightening torque 50Nm.Check that the periphery plates overlap correctly; see illustration.Ostberg recommends that inspections be carried out at least once per year.

Other rotor checks

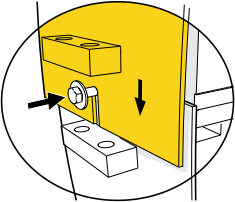

Check the rotor sits square in the casing. Adjust vertical and horizontal alignment as necessary.Check the rotor spins freely. Adjust brushsealing to ensure contact with the rotor or side plates.Ostberg recommends that inspections be carried out at least once per year.

Wear parts

Seals and drive belts are classed as wear parts and should be checked regularly.Ostberg recommends that inspections be carried out at least once per year.

Seals

Check that brushsealing seal against the rotor or side plates. Adjust as necessary. This should be done for the first time 2-3 weeks after commissioning.

Drive belt, hanging motor bracket

Check the motor bracket is suspended at a 20-45° angle to the horizontal. Adjust drive belt length as necessary.Check belt locks and drive belt condition.Drive belt, fixed motor bracketCheck the round belt does not slip.Check belt joint and condition.