Heat and humidity recovery

Heat recovery

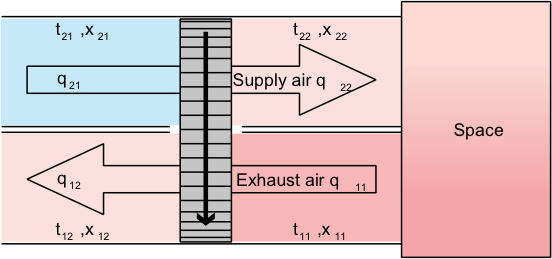

According to the fundamental laws of thermodynamics, heat energy is transported from the warmer to the cooler substance. Similarly, during the winter, sensible heat energy in exhaust air is transferred to the rotor matrix, and from the rotor matrix to the cooler supply air. The amount of heat transfer is generally specified by the temperature efficiency.

The temperature efficiency of rotary heat exchangers in contra-flow operations is usually between 70–90% and for the supply air side is calculated according to the following equation:

ηt = (t22 – t21)/ (t11 – t21)

Temperature efficiency can be determined relatively easily in terms of both measurement and theory. It is largely dependent on the size of the heat transfer surface area, rotor material, air speed through the rotor matrix channels and rotation speed.

Heat transfer surface area is in turn a function of the structure’s well height and design. A simple rule of thumb is that reducing well height increases the heat transfer surface area and thus temperature efficiency.

An important parameter that affects temperature efficiency is airflow and the resultant face velocity on the rotor surface. The Reynold number in the rotor matrix is extremely low, which results in laminar airflow. The adjacent diagram shows temperature efficiency depending on airflow. In face velocity ranges of 5 down to 1.5 m/s, temperature efficiency increase is almost linear and reaches maximum at around 1.2 m/s. At lower face velocities, temperature efficiency falls again.

The greater the outside airflow is in relation to exhaust airflow, the lower the temperature efficiency, and vice versa. Furthermore, rotor speed should be around 12 rounds per minute for optimal heat recovery. If rpm are reduced, temperature efficiency drops.

Furthermore, temperature efficiency is not dependant on the relationship to air temperature, which makes it easier to calculate the recovery rate for varying air temperatures.

Humidity recovery

Humidity efficiency depends on temperature and humidity content in outside and exhaust air and is thus not as easy to calculate as temperature efficiency. Humidity efficiency is defined by the following equation:

ηf = (x22 – x21)/ (x11 – x21)

In general, there are two humidity transfer principles:

Humidity transfer via condensation and evaporation in condensation rotors

Humidity transfer via physical adsorption and desorption through hygroscopic or sorption rotors

The following table provides an overview of general rotor types and their humidity recovery methods:

| Type of rotor | Condensation rotor (ST1-O, AK2-O) | Hygroscopic rotor (STE1-O, SH1-O) | Sorption rotor (HM1-O) |

|---|---|---|---|

| Rotor matrix | Polished or epoxy-coated aluminium | Oxidized aluminium surface with hygroscopic capacity | Surface with sorption coating (3Å) molecular sieve) |

| Humidity transfer principle | Humidity transfer when condensation is present | Lower humidity transfer via adsorption and when condensation is present | High humidity transfer via adsorption |

| Eurovent classification (no condensation) | No humidity efficiency | Humidity efficiency < 70% of temperature efficiency | Humidity efficiency > 70% of temperature efficiency |

Humidity transfer by condensation

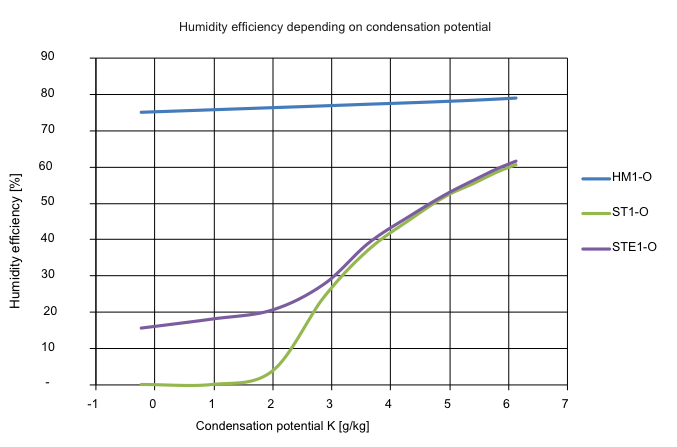

Condensation rotors transfer humidity only when condensation occurs on the exhaust side and is taken up through evaporation by the supply side. Thus humidity efficiency is directly dependent on the amount of condensation on the exhaust side and the amount of humidity taken up on the supply side. The maximum humidity-transfer potential is the difference between exhaust air humidity content and the outside air temperature dew point, aka condensation potential κ.

Condensation potential is independent of air temperature and is a direct measurement of humidity transfer due to condensation. The greater the condensation potential, the greater the amount of condensate on the exhaust side, and thus the greater the humidity efficiency. If the condensation potential is 0, no humidity transfer via condensation can take place. Negative condensation potential describes the summer case and humidity transfer only takes place via physical adsorption.

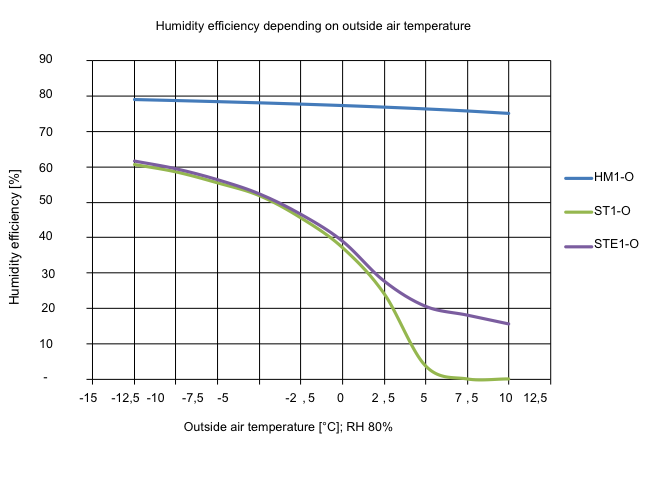

The following graph shows humidity efficiency depending on condensation potential and outside air temperature. Humidity efficiency drops with falling condensation potential.

Humidity transfer through hygroscopy

The rotor matrix on a hygroscopic rotor is treated by oxidation in such a way that a capillary surface structure with adsorption properties is formed. Up until the 1990s it was thought that hygroscopic rotors transferred humidity solely via adsorption and desorption, and therefore humidity efficiency was almost constant and not dependent on condensation potential. However, today we know that hygroscopic rotors reach their best humidity efficiency at low outside air temperatures where humidity is transferred via condensation.

Humidity efficiency decreases as outside air temperature rises. Compared to condensation rotors, hygroscopic rotors transfer a smaller proportion of humidity without condensation occuring (summer time).

Humidity transfer by sorption

Sorption rotors have a special coating that consists of a 3Å molecular sieve, and humidity transfer takes place solely through adsorption and desorption. Humidity efficiency depends on sorption layer coating thickness, adsorption capacity, polarity and air temperature differential. Adsorption kinetics, which is the speed of the adsorption and desorption process as absorbed and released sorption energy, also plays an important part.

Because humidity transfer depends solely on sorption, the condensation potential does not effect the humidity efficiency. The humidity efficiency graph for sorption rotors shows a slight reduction with reduced temperature differential between outside and exhaust air. This is because temperature differential forms an important part of the impetus behind the adsorption and desorption process.

Process in mollier diagram

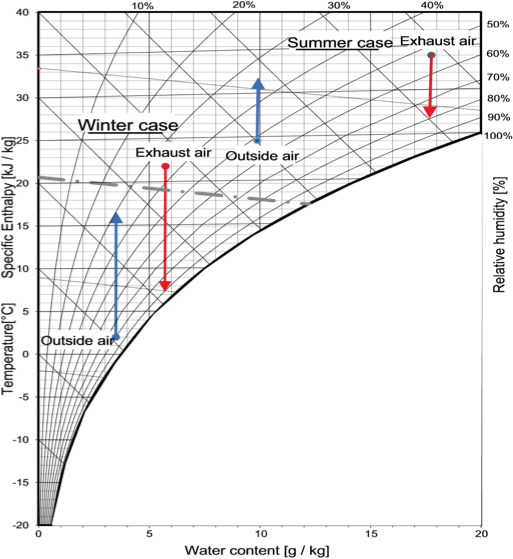

Condensation rotors

Condensation rotors only transfer sensible energy and no airborne humidity if no condensation is present. In the Mollier diagram the process graphs are vertical as air temperature alone is changed through the rotor.

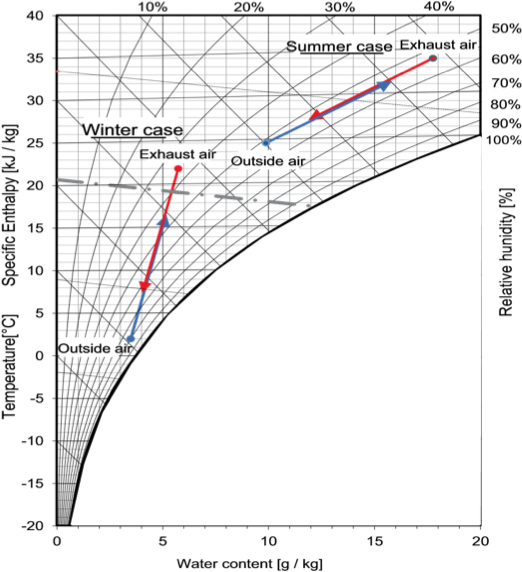

Hygroscopic and sorption rotors

Hygroscopic and sorption rotors transfer sensible and latent energy. The process graphs run at an angle through the diagram as temperature and humidity content change. Humidity efficiency for sorption rotors is higher than that of hygroscopic rotors.