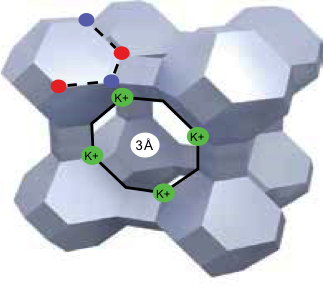

3Å molecular sieves

A molecular sieve is a material with uniform size pores (very small holes) . The diameter of a molecular sieve is measured in ångströms (Å). 3Å molecular sieves do not adsorb molecules whose diameters are larger than 3 Å. While H2O diameter is smaller than 3Å, molecules sieves can adsorb it.

Ostberg only uses a 3Å molecular sieve as a sorption coating, which in comparison to traditional sorption coatings has a selective adsorption ability ≤ 3 Å, i.e. airborne humidity (H2O = water molecule = 2.7 Å). Installations and tests show that a 3Å molecular sieve is the best choice for reducing the risk of odour transfer via the sorption coating.

Sorption rotors

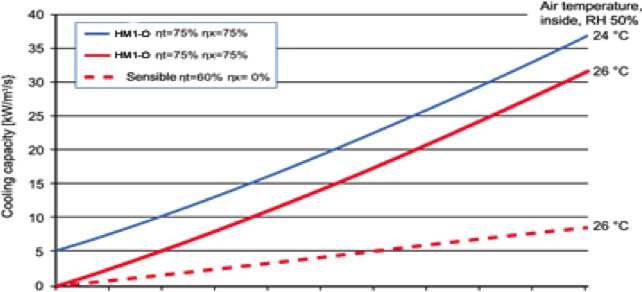

Ostberg Molecular Sieve 3Å HM1 rotors provide exceptionally high humidity efficiency up to 85%. Sorption rotors provide an excellent method of cooling and de-humidifying outside air before it reaches the air handling unit cooling coil.

Direct investment pay off

• Lower investment cost in cooling capacity

• Lower energy consumption in cooling period

• Better indoor air quality

– Minimum Carry Over

– Increased humidity in winter season

• Lower investment and running costs for humidification

• Better performance for dry cooling systems

• Increase cooling capacity in existing systems

• 5-10 °C lower temperature for freezing protection

Advantages of 3Å molecular sieves

The Ostberg HM1 Molecular Sieve 3Å provides high selectivity for water molecule absorption (2.7Å size).

• Performance of 3Å technology is proven in several international and independent studies

• It is recommended in cases where cross contamination needs to be minimized

• Minimized Carry Over of VOC’s from exhaust air to supply air

Lower investment costs in cooling capacity both in AHU’s and cooling system

• The cooling capacity saving is 20 – 50%

• The required cooling capacity will decrease by 10- 25 kW/m3/s air flow compared to sensible energy recovery systems

• Smaller compressors, condensers or cooling towers or higher evaporation and lower condensing temperatures

• Smaller electrical connection costs and power consumption in cooling system

• Lower water flows to cooling coils and smaller pipe works and valves

• Savings in cooling equipment investments are higher than additional cost of sorption treatment of the rotor

Lower investment cost in supply air humidification

• Supply air humidification equipment will be smaller, due to high rate of humidity recovery from the exhaust air

Lower running costs of ventilation, cooling and humidification

• Cooling recovery in summer time

• Humidity recovery in winter time

Better working conditions for dry cooling systems (chilled ceilings or beams)

• Almost constant humidity efficiency provides effective dehumidification of outside air in extreme summer conditions

• Smaller requirement for raised water temperature to unit

Better indoor air quality during winter

• High humidity recovery from exhaust air during winter season