Rotary heat exchangers

Energy recovery

Ostberg rotary heat exchangers are classified as regenerative air-to-air energy recovery units. The primary function of a regenerative air-to-air energy recovery unit is the transfer of sensible (temperature) and latent (humidity) energy between exhaust and supply airflows. Regenerative energy recovery units are very important for energy conservation in ventilation installations that treat outside air to ensure good indoor climate and air quality.

General principle of rotary heat exchangers

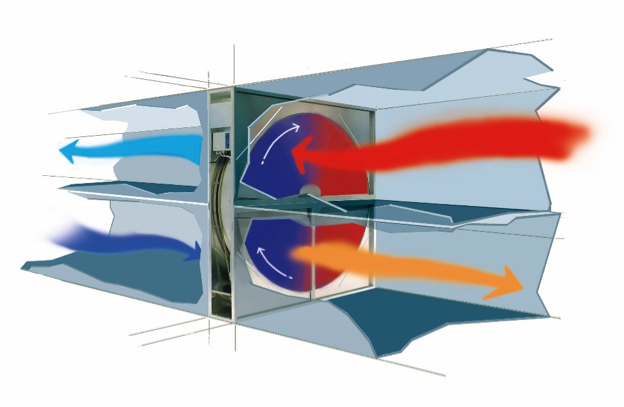

Rotary heat exchangers belong to the group regenerative heat exchangers. Rotor movement means that exhaust air and supply air pass the rotor medium alternately. A major proportion of the energy in the exhaust air is transferred to the supply air via the rotor medium. Thanks to the alternating airflow direction, the rotor is self cleaning and frost proof to a large extent. The ability to recover both thermal (sensible) and humidity (latent) energy makes rotary heat exchangers extremely efficient. Efficiency between 70-90% with a pressure drop under 200 Pa is normal for rotary heat exchangers, and efficiency is easily adjusted by regulating motor rpm.

The rotary heat exchangers is connected on the exhaust side to the outlet and supply ducts and onthe supply side to the supply and exhaust ducts. In this way the air streams pass the rotor matrix in opposite directions, which provides the greatest degree of recovery compared to cross or parallelflow operation.

Both air streams pass the rotor simultaneously and continuously, and the rotor is heated and cooled within one round (revolution). Energy from exhaust air is transferred to the rotor matrix and then from the rotor matrix to outside air.

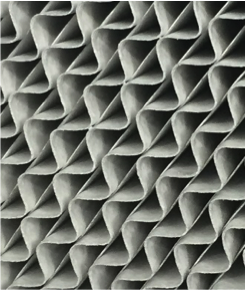

The rotor matrix consists of many small, sinusoidal channels made from thin aluminium foil. Depending on the desired level of recovery, channel height varies between 1.5 and 2.7 mm. The rotor matrix is between 100 and 250 mm thick; 200 mm is suitable for most installations. Regenerative systems are extremely attractive due to their high continuous recovery rates and minimal installation depths.

Untreated aluminium foil is used for sensible heat recovery. Epoxy-coated aluminium or seawater resistant foil with higher magnesium content is best suited in installations in aggressive environments such as industrial or maritime locations. Sensible rotors only transfer humidity during the winter when exhaust air condenses in the rotor matrix and is taken up by the supply air stream.

Hygroscopic or sorption-treated rotors transfer airborne humidity (latent energy) year round. The aluminium foil in hygroscopic rotors is oxidized to create a surface that transfers humidity. Sorption rotor foil is permanently coated with sorption material of the type 3Å molecular sieve, which has an extremely high humidity transfer capacity.